-

WhatsAPP: +86 18706448138

-

Tengzhou, Shandong, China

Unlocking Efficiency in Your Workshop: The Ultimate Guide to Commercial Tramp Oil Skimmers

Discover how a commercial tramp oil skimmer boosts coolant performance, extends tool life, and reduces costs in CNC and machining shops.

If you’re running a machining shop, metalworking facility, or industrial production environment, you’ve probably encountered the persistent problem of tramp oil contamination. Tramp oil not only degrades coolant quality and shortens tool life, but it also creates a breeding ground for bacteria and odors that can compromise both product quality and employee health. One of the most effective solutions you can implement is a commercial tramp oil skimmer.

In this comprehensive guide, you’ll learn everything you need to know about tramp oil skimmers — how they work, why they matter, how to choose the right one, real-world case studies, cost-benefit insights, installation tips, maintenance best practices, and more. By the end of this article, you’ll be equipped with actionable knowledge that can help you optimize your fluid management strategy and improve your facility’s overall performance.

Table of Contents

What Is Tramp Oil — And Why It’s a Hidden Cost in Your Facility

Tramp oil is any unwanted oil that floats on the surface of your cutting fluid, coolant tank, or wash solution. It originates from sources such as:

- Hydraulic leaks

- Machine way oils

- Gearbox oils

- Operator handling and splash-out

Though it may seem harmless at first, tramp oil gradually builds up and leads to:

- Rapid degradation of coolant chemistry

- Increased bacterial and fungal growth

- Poor surface finish

- Shortened tool life

- Higher overall fluid replacement costs

The hidden nature of tramp oil means many shops only realize the true cost once machining issues start emerging.

How a Commercial Tramp Oil Skimmer Works

Commercial tramp oil skimmers are engineered to remove floating oils from fluid surfaces without removing valuable coolants or additives. They work based on physical surface tension differences between tramp oil and water-based fluids.

Most effective skimmers employ one of these basic mechanisms:

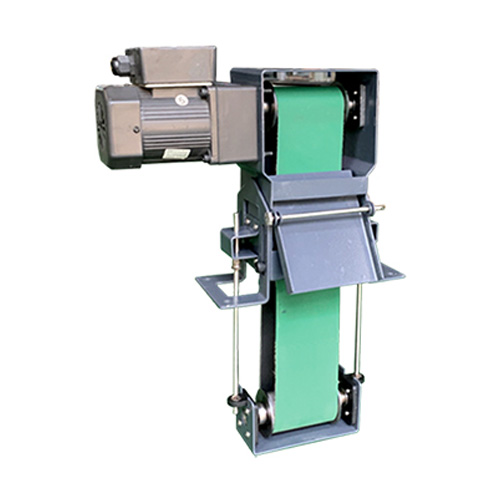

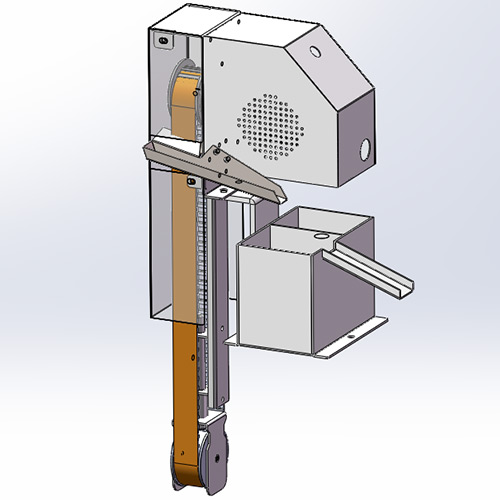

Belt Skimming

A continuous belt rotates through the fluid surface. Oil adheres to the belt and is collected in a separate chamber.

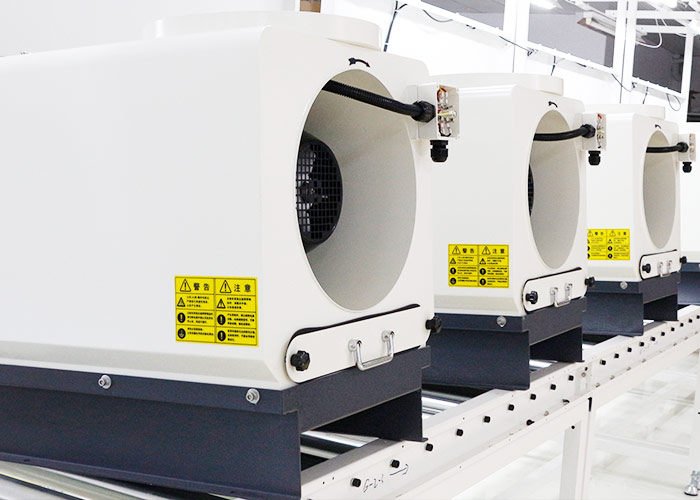

Disc or Drum Skimming

A rotating disc or drum picks up oil from the surface via surface tension and transfers it to a wiper blade.

Tube Skimming

A perforated tube skimmer uses capillary action to draw oil into a collector.

Each mechanism has its own advantages depending on fluid type, amount of tramp oil, and tank geometry.

For a basic technical overview of fluid surface tension and skimming science, see Encyclopedia of Surface and Colloid Science.

External Link: https://onlinelibrary.wiley.com/doi/book/10.1002/9780470140863

Types of Tramp Oil Skimmers and Their Applications

To ensure optimal performance, it’s important to match the right skimmer to your application. Here’s how they compare:

| Skimmer Type | Best For | Advantages | Limitations |

|---|---|---|---|

| Belt Skimmer | Large tanks with heavy oil | High capacity, continuous removal | Requires regular cleaning |

| Disc/Drum Skimmer | Smaller tanks | Compact, efficient surface removal | Limited to lighter oil volumes |

| Tube Skimmer | Wash tanks and sumps | Low-cost, simple design | Lower removal rate |

| Floating Skimmer | Irregular fluid levels | Self-adjusts to surface | Slightly higher maintenance |

This table will help you narrow your choice based on the volume of tramp oil, tank size, and intensity of contamination.

Key Selection Criteria: Choose the Right Skimmer for Your Needs

Before purchasing a tramp oil skimmer, be sure to evaluate these key factors:

Oil Removal Rate

Measured in gallons per hour (GPH), this tells you how much oil the skimmer can remove. Heavily contaminated systems require high GPH units.

Fluid Compatibility

Ensure the skimmer materials (belts/discs/tubes) are compatible with your coolant chemistry.

Tank Geometry

The shape and size of your tank influence skimmer placement and effectiveness.

Automation and Controls

Advanced units offer automatic on/off switching based on oil levels, saving energy and wear.

Ease of Maintenance

Look for accessible collection trays and replaceable media to minimize downtime.

For basic guidelines on selecting fluid management equipment, you can refer to this industry resource:

External Link: https://www.cfmetalsupply.com/resources/coolant-management

Real-World Case Study: Cutting Fluid Optimization in a CNC Shop

Background

A mid-sized CNC machining facility was experiencing recurring coolant breakdown and machining defects. Investigation revealed significant tramp oil accumulation in tool sumps and coolant reservoirs.

Initial Conditions:

- Daily coolant change-outs due to foul odor

- Frequent bacterial contamination

- Poor surface finishes on high-precision parts

Action Taken

A commercial tramp oil skimmer system was installed on all major coolant tanks. Operators were trained to:

- Skim oil at the start of each shift

- Record oil volume removed

- Monitor coolant condition weekly

Results Over 12 Weeks

| Metric | Pre-Skimmer | Post-Skimmer (12 weeks) |

|---|---|---|

| Coolant Change Frequency | Weekly | Quarterly |

| Bacterial Outbreaks | 3 per month | 0 |

| Tool Life (avg.) | 10 hours | 18 hours |

| Fluid Cost Savings | — | 45% reduction |

| Surface Finish Defects | 7% of parts | 1% of parts |

Key Takeaways

- Skimming eliminated the top layer of tramp oil, enabling chemical additives to remain effective.

- Bacterial growth was dramatically reduced, improving shop hygiene.

- Tool life increased due to better thermal transfer in clean coolants.

ROI Analysis: How Tramp Oil Skimmers Save You Money

Though initial investment may seem significant, the long-term savings are compelling. A typical return on investment (ROI) analysis includes:

Cost Categories

- Skimmer purchase & installation

- Routine maintenance

- Coolant additive savings

- Coolant disposal cost reduction

- Extended tool life

- Reduced machine downtime

Example Calculation

In the case study above, if coolant replacement costs $500 per month, and the shop reduced that by 45%, that’s a savings of $225 per month, or $2,700 per year — just from coolant alone. Extended tool life and fewer defects multiply total savings.

For a broader overview of coolant ROI in manufacturing, check this industry publication:

External Link: https://www.machinedesign.com/industrial-fluid-management/article/21130040/coolant-management-solutions

Installation & Maintenance Best Practices

Installation Tips

✔ Position skimmer so it contacts only the fluid surface

✔ Avoid zones with heavy splash or turbulence

✔ Ensure easy access for maintenance

Daily Checks

- Ensure oil collection pan is not full

- Check for belt/disc wear

- Confirm power supply and controls

Weekly Tasks

- Remove accumulated oil and dispose according to regulatory norms

- Clean skimming media for optimal adhesion

- Inspect fluid chemistry

Proper installation and proactive maintenance will maximize skimmer effectiveness and lifespan.

Environmental and Health Benefits

Removing tramp oil does more than just protect machinery — it reduces environmental and health risks:

Reduced Bacterial Growth

Tramp oil feeds bacteria, leading to foul odors and potential respiratory issues.

Less Waste Disposal

By keeping coolants cleaner longer, you reduce hazardous waste disposal frequency.

For environmental handling standards on industrial fluids, you can refer to EPA guidelines:

External Link: https://www.epa.gov/industrial-waste

Common Mistakes to Avoid

❌ Placing the skimmer too deep in the tank

❌ Ignoring regular maintenance schedules

❌ Not training operators on why tramp oil matters

❌ Using incompatible skimmer media for your fluid type

Avoiding these errors ensures you get the most out of your investment.

Conclusion

Implementing a commercial tramp oil skimmer is one of the most cost-effective and impactful steps you can take to improve fluid cleanliness, enhance machining performance, and reduce operating costs in your facility. From understanding the science behind tramp oil to choosing the right technology and maintaining it properly, this guide equips you with expert insights and practical strategies to elevate your shop’s efficiency.

If you’re ready to take the next step, start by evaluating your fluid systems today — the savings and performance improvements could transform your operations.

FAQ

How often should I run my tramp oil skimmer?

Ideally, run it throughout the workday or at the start of each shift to prevent buildup.

Will a skimmer remove emulsified oil?

Standard skimmers target free oil on the surface. For emulsified oil, you may need additional filtration or chemical treatment.

Can I retrofit a skimmer to existing tanks?

Yes — most commercial skimmers are designed for retrofit. Ensure proper mounting and power access.

How do I dispose of the collected oil?

Follow your local hazardous waste disposal regulations. Collected oil may be recyclable.

Does tramp oil affect machining accuracy?

Yes — tramp oil can reduce coolant performance, leading to higher temperatures and lower precision.