-

WhatsAPP: +86 18706448138

-

Tengzhou, Shandong, China

The Ultimate Guide to Commercial Oil Mist Collectors for Factories and Workshops

Learn how commercial oil mist collectors improve air quality, protect machinery, and enhance safety in CNC and metalworking workshops.

Table of Contents

What is a Commercial Oil Mist Collector?

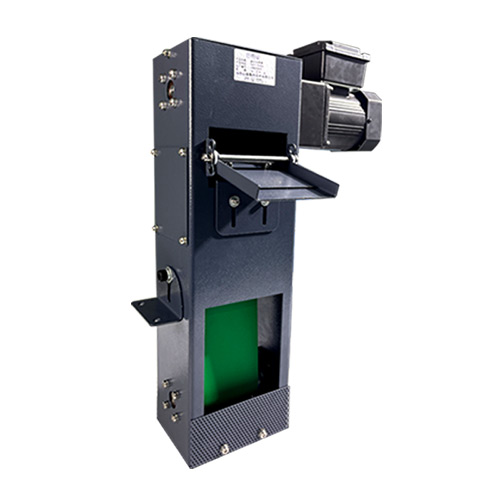

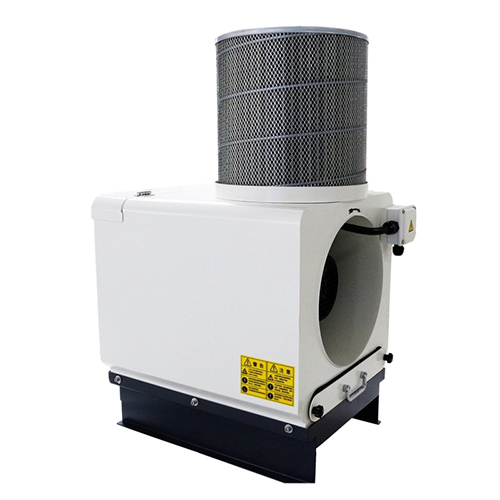

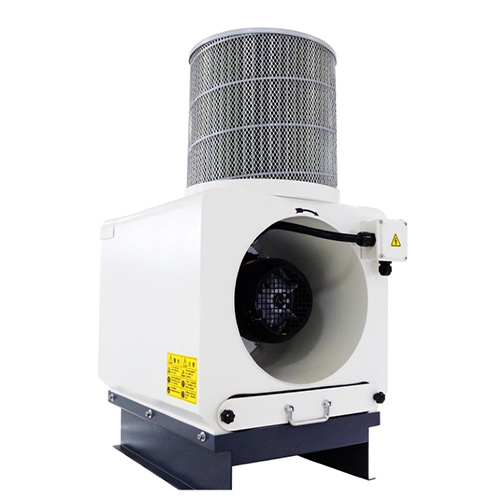

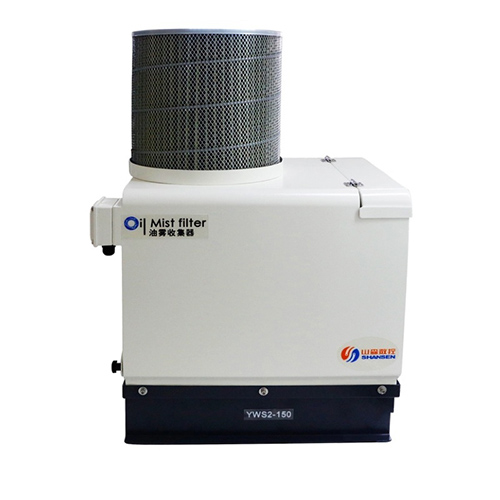

A commercial oil mist collector is a critical piece of equipment designed to capture oil mist, smoke, and other airborne particles generated during metalworking and CNC machining processes. Unlike standard industrial air purifiers, oil mist collectors are specifically engineered to handle oily contaminants and ensure a safe, clean, and efficient working environment.

These collectors typically consist of a fan, filtration system, and mist separation components that remove harmful particles before they escape into the workshop. High-performance models can capture up to 99% of airborne oil particles, protecting both machinery and employees.

The main difference between commercial and industrial models lies in capacity and airflow. Commercial units are optimized for smaller workshops or specific machining areas, whereas industrial collectors are designed for large-scale factories with multiple machines operating simultaneously.

Benefits of Using a Commercial Oil Mist Collector

Installing a commercial oil mist collector in your facility brings numerous advantages:

- Improved Air Quality: Removes harmful oil aerosols and fine particles from CNC machines, metalworking equipment, and other industrial processes.

- Reduced Machinery Maintenance: By capturing oil mist before it settles on machines, collectors reduce downtime and extend equipment life.

- Enhanced Safety and Compliance: Clean air reduces the risk of respiratory issues among employees and helps factories comply with OSHA and other air quality regulations.

- Energy Efficiency: Modern collectors often consume less power while maintaining high filtration efficiency, lowering operational costs.

Types of Commercial Oil Mist Collectors

Choosing the right type of oil mist collector depends on your workshop’s specific needs. Common types include:

Wet vs Dry Collectors

- Wet collectors use a liquid (usually water) to trap oil particles, making them ideal for high-volume applications.

- Dry collectors rely on filter media and are suitable for smaller shops or light-duty operations.

High-Capacity vs Compact Models

- High-capacity models can serve multiple machines simultaneously, perfect for larger factories.

- Compact units are portable and fit in tighter spaces, ideal for localized CNC machining areas.

Energy-Efficient Collectors

- Designed with advanced fans and filters to maximize airflow while minimizing electricity use.

- Often paired with smart controls for automated operation and lower running costs.

How to Choose the Right Commercial Oil Mist Collector

When selecting a collector, consider these critical factors:

| Factor | Description | Recommended Option |

|---|---|---|

| Airflow | Measured in CFM (cubic feet per minute), determines coverage area | Choose higher CFM for multiple machines |

| Filtration Efficiency | Percentage of particles captured | ≥ 99% for oil mist removal |

| Noise Level | Operational sound in dB | Below 70 dB for workshops |

| Maintenance | Frequency and ease of filter replacement | Opt for easy-access filter systems |

| Size & Space | Physical dimensions | Ensure space compatibility with existing machinery |

Manufacturers should always consider machine type (CNC, milling, grinding) and workshop layout when choosing the optimal model. Buying directly from a reputable manufacturer ensures customization options, better warranty, and support.

Installation and Maintenance Tips

Proper installation and routine maintenance are key for optimal performance:

- Installation: Place the collector near the source of mist, ideally at or slightly above the machine height. Connect ductwork efficiently for maximum airflow.

- Maintenance: Replace or clean filters according to manufacturer guidelines. Wet collectors require periodic water changes to prevent bacterial growth.

- Troubleshooting: Common issues include reduced airflow, excessive noise, or oil leaks. Regular inspections help prevent downtime.

Commercial Oil Mist Collector vs Industrial Air Purifier

While both devices improve air quality, the two are not interchangeable:

- Commercial Oil Mist Collector: Specifically captures oily aerosols, smoke, and fine metal particles. Ideal for CNC machining, metal cutting, and fabrication.

- Industrial Air Purifier: General-purpose filtration, suitable for dust, pollen, or fumes, but often ineffective for oil mist.

In workshops with metalworking or machining processes, investing in a dedicated oil mist collector ensures regulatory compliance and operational safety.

Cost and ROI of Commercial Oil Mist Collectors

The initial price of a collector can vary based on capacity, filtration efficiency, and brand, typically ranging from $1,000 to $10,000 for commercial models.

Return on Investment (ROI) can be substantial:

- Reduced maintenance costs for machinery

- Extended machine lifespan

- Lower energy consumption with modern, energy-efficient models

- Fewer employee health issues and improved productivity

Purchasing directly from a manufacturer can save up to 20–30% compared to third-party suppliers, while also offering customization options for specific factory layouts.

Top Applications of Commercial Oil Mist Collectors

Commercial oil mist collectors are widely used across multiple industrial sectors:

- CNC Machining Workshops: Captures mist generated during cutting, drilling, and milling operations.

- Metalworking and Fabrication Factories: Reduces airborne oil and improves shop floor safety.

- Automotive Industry: Maintains clean environments in engine assembly and parts manufacturing.

- Aerospace & Electronics: Ensures precise, clean air for high-precision operations.

Choosing the Right Manufacturer

Working with a trusted manufacturer provides several benefits:

- Customization: Collectors can be tailored for airflow, filter type, and size.

- Quality Assurance: Factory-direct products undergo strict testing and certification.

- Technical Support: Access to expert guidance for installation, maintenance, and troubleshooting.

Choosing the right partner ensures that your collector performs efficiently and lasts longer, protecting both machinery and employees.

Conclusion

A commercial oil mist collector is a vital investment for factories and workshops, improving air quality, protecting machinery, and enhancing workplace safety. As a manufacturer, offering high-quality, efficient collectors ensures your customers benefit from reduced maintenance costs and regulatory compliance.

Choosing the right collector, installing it correctly, and maintaining it regularly can deliver significant ROI for your operations. Investing in a manufacturer-made oil mist collector guarantees reliability, customization, and long-term support.

If you are looking to enhance your CNC or metalworking workshop environment, contacting a trusted commercial oil mist collector manufacturer is the first step toward cleaner, safer, and more efficient production.

FAQ

Q1: What is a commercial oil mist collector used for?

A1: A commercial oil mist collector removes oil mist, smoke, and fine metal particles from CNC machines, metalworking, and other industrial processes, improving air quality and protecting machinery.

Q2: How often should I maintain my commercial oil mist collector?

A2: Maintenance depends on usage, but filters typically need replacement every 3–6 months. Regular cleaning ensures optimal airflow and filtration efficiency.

Q3: Can one collector handle multiple machines?

A3: Yes, high-capacity commercial oil mist collectors can serve several machines simultaneously, making them ideal for workshops or small factories.

Q4: What is the difference between wet and dry oil mist collectors?

A4: Wet collectors use liquid to trap oil particles and handle high-volume applications, while dry collectors rely on filter media and are suitable for smaller workshops or light-duty operations.

Q5: Why should I buy a commercial oil mist collector directly from the manufacturer?

A5: Purchasing from a manufacturer ensures product reliability, warranty, customization options, and expert technical support, often at a lower cost than third-party suppliers.