-

WhatsAPP: +86 18706448138

-

Tengzhou, Shandong, China

Best Oil Skimmer: A Manufacturer’s Guide to Choosing the Right Solution

Discover how the best oil skimmer improves industrial efficiency, reduces costs, and ensures environmental compliance. Expert tips from the manufacturer.

Table of Contents

When it comes to maintaining clean industrial fluids, selecting the best oil skimmer is critical. As a manufacturer of high-quality oil skimmers, we understand the challenges industries face when managing oil-contaminated water, coolant, or hydraulic fluids. Choosing the right oil skimmer not only improves efficiency but also reduces costs, extends equipment lifespan, and ensures compliance with environmental regulations.

In this guide, we will explore everything you need to know about best oil skimmers, including types, features, maintenance tips, and practical applications.

What is a Best Oil Skimmer and How Does It Work?

An oil skimmer is a device designed to remove floating oil from liquid surfaces. In industrial settings, oil contamination can reduce the effectiveness of coolants, damage equipment, and lead to regulatory penalties. The best oil skimmer efficiently separates oil from water or coolant, maintaining operational efficiency.

Working Principles of Industrial Oil Skimmers

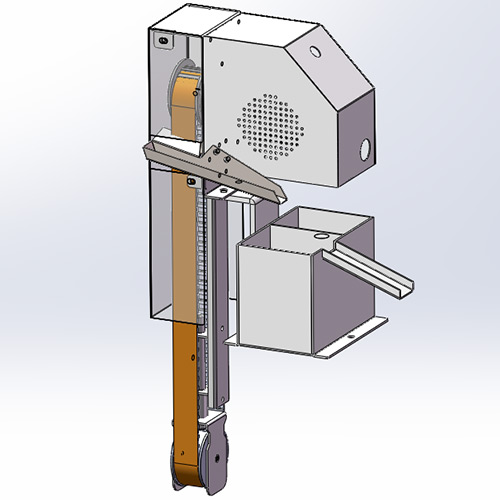

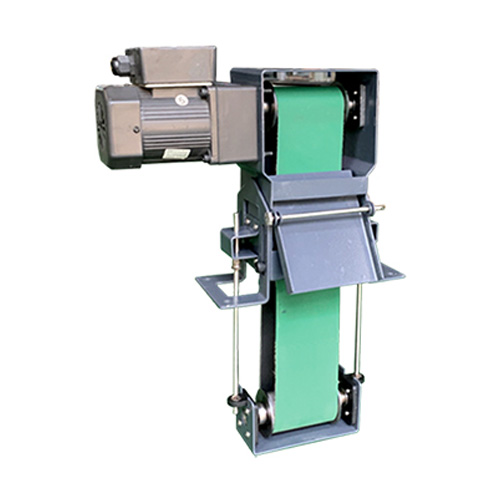

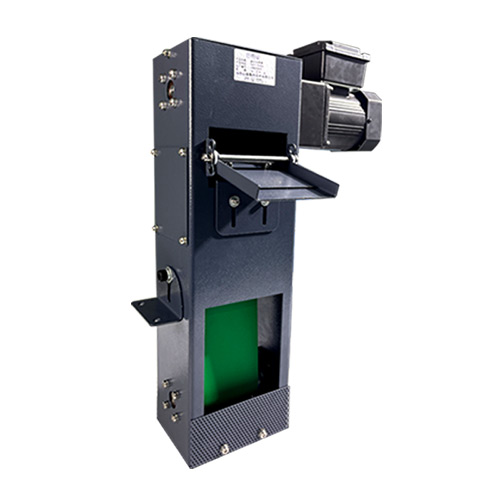

- Belt skimmers: Continuous belts collect oil and transport it to a storage container.

- Disc skimmers: Rotating discs attract oil and transfer it to a collection system.

- Tube skimmers: Floating tubes absorb oil from liquid surfaces for removal.

Automatic oil skimmers operate continuously with minimal labor, while manual skimmers are cost-effective for smaller applications.

Types of Best Oil Skimmers for Industrial Applications

Selecting the correct type of oil skimmer depends on your application.

- Belt Oil Skimmers: Ideal for large tanks, high-efficiency oil removal.

- Disc Oil Skimmers: Best for moderate flow rates and high oil recovery.

- Tube Oil Skimmers: Suitable for small tanks or portable applications.

- Portable vs Fixed Skimmers: Portable skimmers offer flexibility; fixed skimmers provide consistent performance for large industrial systems.

Key Features to Look for in the Best Oil Skimmer

When evaluating an oil skimmer, the following features are essential:

- Oil Removal Efficiency and Capacity: Ensures the skimmer can handle the volume of oil generated.

- Material Compatibility: The skimmer must work with coolant, hydraulic oil, wastewater, or other fluids.

- Durability and Corrosion Resistance: High-quality materials extend lifespan, especially in harsh environments.

- Ease of Maintenance: Quick cleaning and simple part replacement reduce downtime.

- Automation Features: Automated skimmers provide continuous oil removal with minimal labor.

Benefits of Using a Best Oil Skimmer in Your Facility

Integrating the oil skimmer into your facility offers multiple advantages:

- Reduces downtime and labor costs by automating oil removal.

- Improves coolant and water quality, enhancing equipment performance.

- Supports environmental compliance by preventing oil contamination in wastewater.

- Prolongs equipment lifespan by reducing exposure to contaminated fluids.

How to Choose the Best Oil Skimmer for Your Needs

Choosing the right skimmer requires careful consideration of your facility’s requirements:

- Tank Size and Industry: Large manufacturing plants require high-capacity skimmers; smaller workshops may use portable units.

- Flow Rate and Oil Removal Capacity: Match skimmer output to your oil generation rate.

- Energy Efficiency and Automation: Automated skimmers reduce manual intervention and optimize energy use.

- Manufacturer Support and Warranty: Reliable support ensures long-term performance and minimal downtime.

Comparison Table: Common Oil Skimmer Types

| Skimmer Type | Suitable Tank Size | Oil Removal Rate | Automation | Maintenance Level |

|---|---|---|---|---|

| Belt Skimmer | Medium to Large | High | Automatic/Manual | Low to Medium |

| Disc Skimmer | Medium | Medium-High | Automatic | Medium |

| Tube Skimmer | Small | Medium | Manual | Low |

| Portable Skimmer | Small to Medium | Medium | Optional | Low |

Maintenance and Troubleshooting Tips for Best Oil Skimmers

Regular maintenance ensures optimal performance of your best oil skimmer:

- Clean belts, discs, and tubes regularly to avoid buildup.

- Replace worn components promptly.

- Check for leaks or misalignment.

- Follow safety guidelines when handling oil and lubricants.

Addressing minor issues early prevents costly downtime and extends the skimmer’s lifespan.

Comparing the Best Oil Skimmer Models on the Market

Not all oil skimmers are created equal. When comparing models:

- Belt vs Disc vs Tube: Belt skimmers typically offer the highest efficiency; disc skimmers are versatile; tube skimmers are portable.

- Price vs Efficiency: Higher upfront costs may be offset by improved performance and lower maintenance.

- Application-Specific Recommendations: Automotive workshops may prefer portable units; manufacturing plants benefit from heavy-duty automatic skimmers.

Environmental and Safety Considerations

Industrial facilities must manage oil contamination responsibly. A best oil skimmer helps reduce environmental pollution by:

- Preventing oil from entering wastewater streams.

- Supporting compliance with industrial regulations.

- Ensuring safe collection and disposal of oil to reduce workplace hazards.

Industry Applications of the Best Oil Skimmer

Oil skimmers are widely used across various industries:

- Automotive Workshops: Removes oil from coolant tanks and wash systems.

- Manufacturing Plants: Maintains clean hydraulic fluids and prevents equipment damage.

- Food Processing and Chemical Industries: Ensures safety and cleanliness in processing fluids.

- Wastewater Treatment and Oil Spill Cleanup: Efficiently separates oil from large water volumes.

Conclusion

Selecting the best oil skimmer is essential for industrial efficiency, environmental compliance, and long-term cost savings. As a manufacturer, we provide reliable, high-performance oil skimmers designed for diverse applications. By choosing the right skimmer and following proper maintenance, facilities can achieve cleaner fluids, safer operations, and improved productivity. Explore our range of industrial oil skimmers today and see the difference a professional, well-engineered solution can make.

FAQ

1. What is the best oil skimmer for industrial applications?

The best oil skimmer for industrial use depends on your tank size and fluid type. Belt and disc skimmers are ideal for large facilities, while tube or portable skimmers work well for smaller setups.

2. How does an automatic oil skimmer work?

An automatic oil skimmer continuously removes oil from the surface of liquids using belts, discs, or tubes, reducing manual labor and improving oil removal efficiency.

3. How do I maintain the best oil skimmer?

Regular cleaning of belts, discs, or tubes, checking for worn parts, and following manufacturer instructions ensures optimal performance and extends the skimmer’s lifespan.

4. Can a best oil skimmer handle coolant and hydraulic oil?

Yes. High-quality industrial oil skimmers are designed to work with various fluids, including coolants, hydraulic oils, and wastewater, without affecting efficiency.

5. Why should I choose a manufacturer-provided oil skimmer?

Purchasing directly from a manufacturer ensures product quality, professional guidance, warranty support, and access to skimmers designed for your specific industry needs.