-

WhatsAPP: +86 18706448138

-

Tengzhou, Shandong, China

Ultimate Guide to Metal Oil Mist Collectors for Industrial Workshops

Learn how metal oil mist collectors improve workshop air quality, protect equipment, and boost efficiency. Expert guide for industrial CNC and lathe shops.

Table of Contents

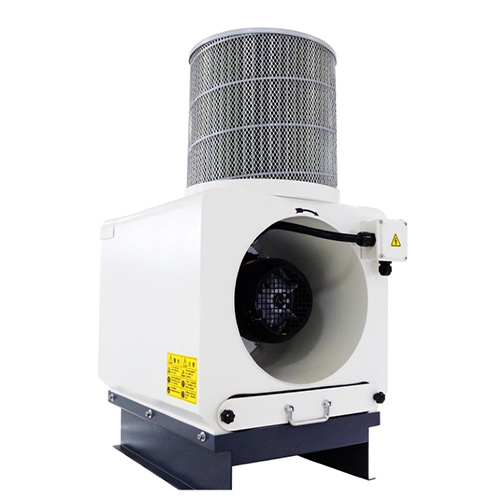

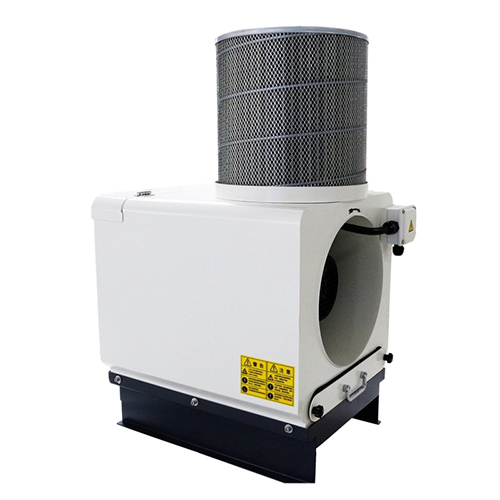

What is a Metal Oil Mist Collector?

A metal oil mist collector is an essential piece of equipment for industrial workshops, especially those operating CNC machines, lathes, and milling equipment. Its primary function is to capture and remove fine oil mist particles produced during metalworking processes, preventing them from spreading into the air and settling on equipment or work surfaces.

Metal oil mist collectors improve air quality, reduce health risks for operators, and maintain a cleaner workshop environment. They are widely used in industries where metal cutting, grinding, or milling generates oil aerosols.

The working principle is straightforward: air containing oil mist is drawn into the collector, where the mist passes through filters or electrostatic plates. The oil droplets are separated from the air, collected in a reservoir, and the cleaned air is returned to the workshop.

Benefits of Using a Metal Oil Mist Collector

Investing in a metal oil mist collector brings numerous advantages:

- Improved Air Quality and Safety – Removing oil mist reduces the risk of respiratory issues and keeps the workshop environment safe.

- Protection of Equipment and Tools – Oil mist can accumulate on machinery, leading to corrosion and reduced efficiency. Collectors prevent this buildup.

- Compliance with Industrial Safety Standards – Many industries require proper air filtration to meet OSHA or ISO safety standards.

- Cost Savings Through Efficient Oil Recovery – Some collectors allow for the reclaimed oil to be reused, reducing operational costs.

Types of Metal Oil Mist Collectors

Metal oil mist collectors come in various types to suit different workshop needs:

- Compact vs Industrial-Scale Collectors – Small workshops often use compact collectors, while larger operations need industrial-scale units.

- Filter-Based vs Electrostatic Oil Mist Collectors – Filter-based systems trap oil particles in high-efficiency filters, whereas electrostatic systems use charged plates to capture finer particles.

- Choosing the Right Collector for Your Workshop – Factors such as airflow requirements, machine types, and workspace size influence the choice.

How to Choose the Right Oil Mist Collector

Selecting the ideal collector involves considering multiple factors:

- Size and Flow Rate – Ensure the collector can handle the airflow produced by your machines.

- Noise Level – Some collectors are quieter and better suited for small workshops.

- Machine Compatibility – Different collectors work better with CNC machines, lathes, or milling machines.

- Energy Efficiency and Maintenance – Look for collectors that save energy and require minimal maintenance.

Installation and Maintenance Tips

Proper installation and maintenance maximize the efficiency and lifespan of your oil mist collector.

- Installation – Position the collector close to the source of oil mist. Connect hoses securely and ensure adequate airflow.

- Routine Maintenance – Replace filters on schedule and empty oil reservoirs regularly. Check for leaks or unusual noises.

- Troubleshooting Common Issues – Poor airflow may indicate clogged filters, while unusual odors or smoke may require professional inspection.

Comparing Metal Oil Mist Collectors to Other Air Filtration Systems

It’s important to understand how oil mist collectors perform compared to other filtration methods:

| Feature | Metal Oil Mist Collector | Electrostatic Oil Collector | Water Mist Collector |

|---|---|---|---|

| Efficiency | High for industrial oil mist | High for fine particles | Moderate, requires water |

| Maintenance | Moderate, filter replacement | High, plate cleaning required | Low, frequent water replacement |

| Energy Usage | Moderate | Moderate | Higher due to water pumping |

| Noise Level | Low to moderate | Low | Moderate |

| Cost | Moderate | High | Low to moderate |

As the table shows, metal oil mist collectors balance efficiency, cost, and ease of maintenance, making them ideal for most metalworking workshops.

Top Factors to Consider Before Buying

Before making a purchase, consider:

- Price vs Quality Balance – Cheaper units may have lower efficiency or shorter lifespan.

- Supplier Reputation and After-Sales Service – As a manufacturer, we emphasize reliability, spare parts availability, and responsive service.

- Durability and Warranty – Look for collectors built with high-quality steel and robust filtration systems.

Real-World Applications and Case Studies

Metal oil mist collectors are widely adopted across industries:

- Reducing Oil Waste – Workshops using collectors can reclaim up to 80% of oil particles for reuse.

- Improving Safety – Operators are less exposed to harmful oil aerosols, decreasing health risks.

- Boosting Productivity – Cleaner machines run more efficiently, reducing downtime and maintenance costs.

Many CNC and lathe operations report noticeable improvements in air quality and overall workflow after installing metal oil mist collectors.

Conclusion

Metal oil mist collectors are essential for modern metalworking workshops, combining safety, efficiency, and cost savings. As a manufacturer, we focus on designing durable, high-performance units that meet industrial standards and provide long-term value.

Investing in a metal oil mist collector not only protects your team and equipment but also improves workshop productivity and compliance with safety regulations. Explore our product range today or contact us for expert guidance on selecting the ideal collector for your needs.

FAQ

1. What is a metal oil mist collector?

A metal oil mist collector is a device designed to remove airborne oil mist generated during metalworking processes like CNC machining and lathe operations, keeping the workshop air clean and safe.

2. Why should I use a metal oil mist collector in my workshop?

Using a metal oil mist collector improves air quality, protects equipment from oil buildup, reduces health risks for operators, and ensures compliance with industrial safety standards.

3. How do I maintain a metal oil mist collector?

Regular maintenance includes replacing filters, emptying the oil reservoir, cleaning components, and checking for leaks or unusual noises to keep the collector operating efficiently.

4. What types of metal oil mist collectors are available?

There are compact units for small workshops, industrial-scale collectors for larger operations, and systems using filter-based or electrostatic technology depending on airflow and particle size requirements.

5. How do I choose the right oil mist collector for my machines?

Consider the airflow rate, machine compatibility (CNC, lathe, or milling), collector size, noise level, energy efficiency, and maintenance requirements to select the most suitable unit.