-

WhatsAPP: +86 18706448138

-

Tengzhou, Shandong, China

Commercial Oil Skimmer: The Complete Guide for Industrial Use and Purchase

Learn how a commercial oil skimmer works, its benefits, and how to choose the right model for your factory. Contact us for custom solutions today!

Table of Contents

What is a Commercial Oil Skimmer?

A commercial oil skimmer is an industrial device designed to remove oil, grease, and other hydrocarbons from water or coolant surfaces efficiently. These systems are widely used in factories, workshops, wastewater treatment plants, and food processing facilities to maintain clean liquids and reduce maintenance costs.

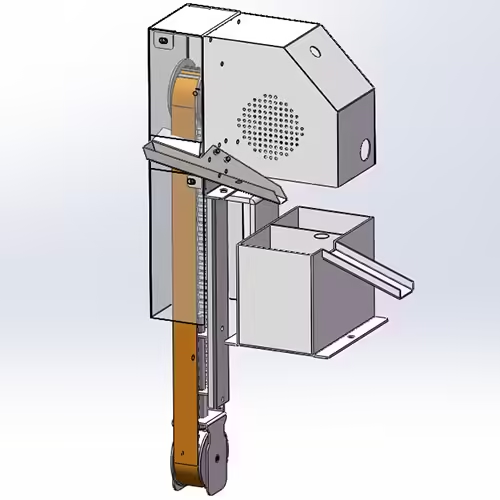

Key Components of a Commercial Oil Skimmer:

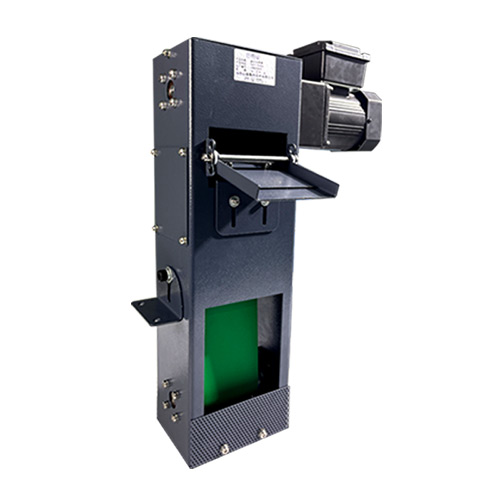

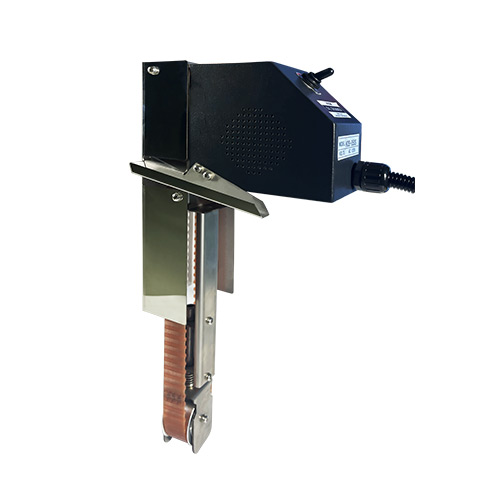

- Skimmer body: The main frame that holds the motor, pump, and skimming mechanism.

- Skimming mechanism: Includes belts, disks, tubes, or ropes that collect floating oil.

- Oil collection container: Stores the separated oil for disposal or recycling.

- Drive system: Powers the movement of the skimming element.

How It Works:

The commercial oil skimmer removes oil from liquid surfaces by using a moving surface (belt, disk, or rope) that attracts and lifts oil while leaving water behind. The collected oil then drains into a container for proper disposal or reuse. This continuous process prevents oil accumulation and protects industrial systems from damage.

Benefits of Using a Commercial Oil Skimmer

Using a commercial oil skimmer brings multiple advantages for industrial operations:

- Reduce Waste and Improve Efficiency

By removing oil from water or coolant systems, skimmers extend the life of industrial fluids, reduce the frequency of replacements, and optimize production efficiency. - Protect Equipment and Reduce Maintenance Costs

Oil contamination can damage pumps, filters, and machinery. A commercial oil skimmer reduces wear and tear, helping factories avoid costly downtime. - Enhance Environmental Compliance

Industrial facilities must comply with environmental regulations regarding wastewater and oil disposal. Skimmers ensure cleaner effluent and reduce environmental penalties. - Cost-Effective Operation

Automated oil skimming reduces labor costs while continuously improving the quality of industrial fluids.

Types of Commercial Oil Skimmers

Industrial oil skimmers come in various types to meet different applications:

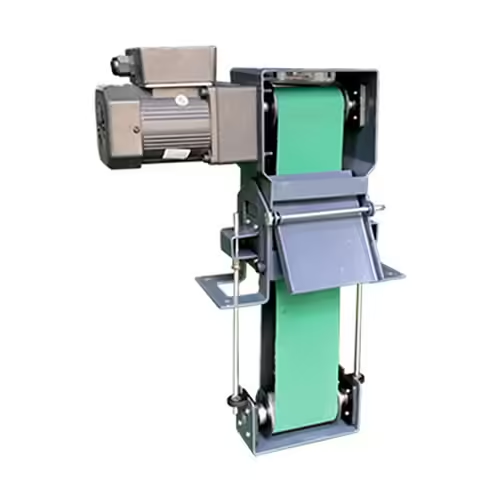

- Belt Oil Skimmers: Ideal for high-capacity, continuous oil removal in coolant tanks or wastewater systems.

- Disk Oil Skimmers: Suitable for smaller volumes or where rapid oil collection is required.

- Tube and Rope Oil Skimmers: Perfect for tanks or containers with low fluid levels or irregular shapes.

| Type | Typical Use | Advantages |

|---|---|---|

| Belt Skimmer | CNC machines, coolant tanks | High capacity, continuous operation, robust |

| Disk Skimmer | Small tanks, workshops | Fast oil removal, compact size |

| Tube/Rope Skimmer | Irregular or shallow tanks | Flexible, low maintenance |

How to Choose the Right Commercial Oil Skimmer

Selecting the right oil skimmer is crucial to maximize efficiency and ROI. Consider the following:

- Capacity Requirements: Determine the volume of oil your system produces daily. Choose a skimmer rated for that capacity.

- Skimmer Material: Stainless steel skimmers are ideal for durability and corrosion resistance.

- Automation Level: Fully automatic skimmers reduce labor and maintain consistent oil removal.

- Industry Application: Match the skimmer type to your system, whether it’s metalworking, CNC machining, wastewater treatment, or food processing.

A well-chosen skimmer ensures optimal performance and longer equipment life.

Commercial Oil Skimmer Applications Across Industries

Commercial oil skimmers are highly versatile and used in multiple industries:

- Metalworking & Machining: Remove cutting oils and coolants from tanks to maintain clean metalworking fluids.

- Industrial Wastewater Treatment: Skim oil from wastewater before discharge or treatment.

- Food Processing & Grease Traps: Reduce oil buildup in kitchens and food manufacturing plants.

- Power Plants & Chemical Industry: Maintain coolant systems and prevent oil contamination in large-scale industrial operations.

Maintenance and Troubleshooting of Commercial Oil Skimmers

Proper maintenance ensures longevity and consistent performance:

- Regular Cleaning: Clean the skimming element and collection container to prevent clogging.

- Belt or Disk Replacement: Replace worn belts or disks to maintain efficiency.

- Common Issues: Skimmer not collecting oil can result from improper alignment, overloaded systems, or worn parts.

- Maximizing Lifespan: Routine inspection, lubrication, and timely part replacement extend service life.

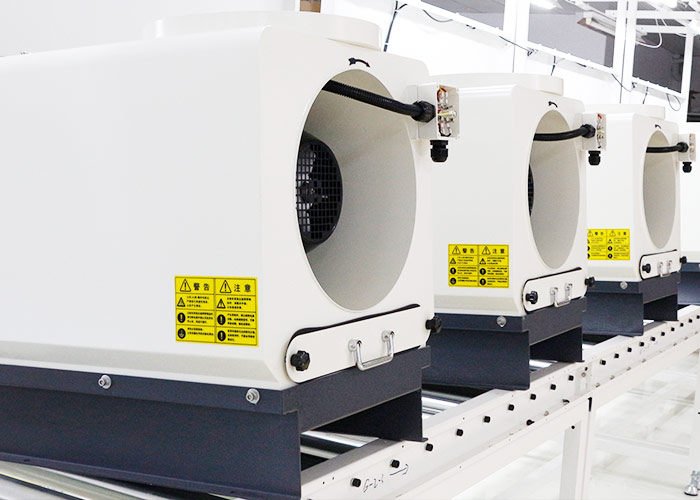

Why Buy Directly From the Manufacturer

Purchasing a commercial oil skimmer directly from the manufacturer offers significant advantages:

- Cost Savings: Avoid middlemen and reduce procurement costs.

- Custom Solutions: Manufacturers can provide skimmers tailored to your tank size, oil type, and automation needs.

- OEM Options & Bulk Orders: Ideal for large-scale operations requiring multiple units.

- Reliable After-Sales Support: Direct access to technical guidance and maintenance services.

Conclusion

A commercial oil skimmer is an essential investment for any industrial facility handling oil, coolant, or wastewater. It improves operational efficiency, protects machinery, ensures compliance with environmental standards, and reduces maintenance costs.

As a manufacturer, we provide high-quality, customizable commercial oil skimmers that meet your industrial needs.

Need a Reliable Commercial Oil Skimmer for Your Factory? Contact us today to get a personalized solution and ensure efficient oil removal for your industrial processes.

FAQ

What is a commercial oil skimmer?

A commercial oil skimmer is a device used in industrial settings to remove oil, grease, and hydrocarbons from water or coolant surfaces efficiently.

How does a commercial oil skimmer work?

It uses a moving element like a belt, disk, or rope to attract and lift floating oil, separating it from water or other liquids for collection.

What industries use commercial oil skimmers?

They are commonly used in metalworking, CNC machining, wastewater treatment, food processing, and power or chemical plants.

How do I choose the right commercial oil skimmer?

Consider factors like tank size, oil type, removal capacity, automation level, and material to match your industrial application.

Why should I buy directly from a commercial oil skimmer manufacturer?

Buying directly ensures cost savings, custom solutions, OEM options, bulk orders, and reliable after-sales support.

Need Help Choosing the Right Commercial Oil Skimmer?

If you’re unsure which commercial oil skimmer is best for your factory or industrial system, our experts are here to guide you. Contact us today for a personalized consultation, and ensure your oil removal process is efficient, safe, and cost-effective. Don’t wait until oil buildup affects your operations—get in touch now to protect your equipment and improve productivity!