-

WhatsAPP: +86 18706448138

-

Tengzhou, Shandong, China

Oil Mist Collector Filter: Manufacturer’s Guide for Industrial CNC Applications

High-efficiency oil mist collector filters for CNC and industrial workshops. Customized solutions directly from the manufacturer.

Welcome to My Blog!

Before we dive into the content, if you’re interested in our products or have any questions, please feel free to visit our Contact Us page on the website. Our team is ready to assist you with inquiries, orders, or any support you may need.

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

As CNC machining speeds increase and cutting fluids are widely used, oil mist has become a common challenge in modern workshops. Airborne oil particles not only affect the health of operators but also accumulate on machine components, causing equipment failures and reducing production efficiency. An efficient oil mist collector filter is no longer optional—it is a critical component for maintaining air quality, protecting equipment, and meeting industrial safety standards.

As a professional oil mist collector filter manufacturer, we provide high-efficiency and customizable filtration solutions designed specifically for CNC and metalworking applications. This comprehensive guide will help you understand how oil mist collector filters work, how to select the right solution for your workshop, and why sourcing directly from a manufacturer ensures long-term reliability, cost savings, and tailored technical support.

What Is an Oil Mist Collector Filter and How Does It Work?

Oil mist is generated when cutting fluids, lubricants, and coolants are atomized during high-speed CNC machining. These fine oil particles spread through the air, contaminating the workspace, creating slippery surfaces, and causing potential respiratory hazards. Over time, accumulated oil can also lead to mechanical failures and increased maintenance costs for CNC machines.

An oil mist collector filter captures these airborne oil particles before clean air is released back into the workshop or exhausted outdoors. It improves both environmental safety and equipment longevity by continuously filtering the contaminated air.

What Causes Oil Mist in CNC Machining?

- High-speed rotation of cutting tools: Faster cutting speeds create more oil droplets.

- Use of oil-based or emulsion cutting fluids: These fluids atomize easily under heat and motion.

- Enclosed or semi-enclosed CNC machines: Limited airflow can concentrate mist inside the enclosure.

- Continuous machining and automated production lines: Longer operating hours lead to more persistent oil mist.

Understanding the source of oil mist is essential to select the right filtration system and prevent recurring issues in your facility.

Oil Mist Collector Filter Working Principle

Oil mist collector filters typically operate through a multi-stage filtration process.

- Pre-filtration captures larger droplets, preventing them from entering finer filtration stages.

- Coalescing filtration combines smaller mist particles into larger droplets that can be collected and reused.

- High-efficiency or HEPA filtration removes ultra-fine particles, ensuring that discharged air meets safety and cleanliness standards.

This layered design ensures high filtration efficiency and stable airflow performance, making the filter suitable for a variety of industrial applications.

Why Oil Mist Collector Filters Are Essential for CNC Workshops

Installing a reliable oil mist collector filter system delivers both operational and economic benefits. Beyond improving air quality, these systems reduce machine downtime, protect employee health, and help workshops comply with industrial safety standards.

Health and Safety Benefits

High concentrations of oil mist in the workplace can cause respiratory issues, skin irritation, and long-term health concerns for employees. By installing an effective oil mist collector filter, CNC workshops can significantly reduce airborne contaminants, ensuring cleaner and safer air. Compliance with local and international industrial safety regulations is also easier with properly filtered work environments.

Protecting CNC Machines and Production Efficiency

Oil mist accumulation on machine components can lead to mechanical malfunctions, electrical failures, and premature wear. A high-quality oil mist collector filter prevents these issues, maintaining optimal machine performance and extending equipment lifespan. Reduced downtime and maintenance costs directly contribute to higher productivity and lower operational expenses, making the investment in filtration systems cost-effective in the long run.

Types of Oil Mist Collector Filters Used in Industrial Applications

Different CNC environments require specific filtration solutions. Choosing the right type ensures efficient oil mist removal, longer filter lifespan, and optimal machine protection.

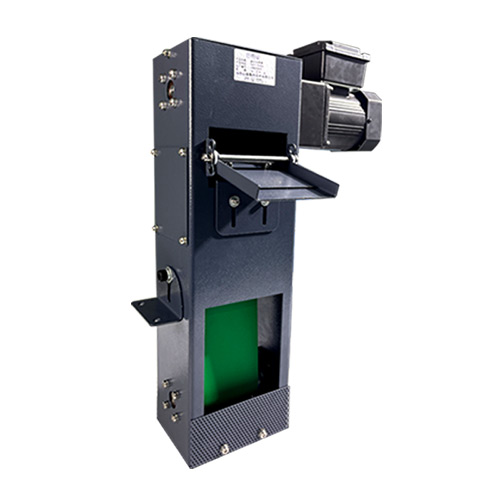

Mechanical Oil Mist Collector Filters

These filters are suitable for capturing larger oil droplets in low-to-medium mist environments. They are often used as the first stage in multi-stage filtration systems to protect finer filters downstream and reduce maintenance frequency.

Coalescing Oil Mist Filters

Coalescing filters are designed to remove fine oil mist from the air. They work by merging tiny oil droplets into larger ones that can be collected and recycled, making them ideal for workshops that aim to reduce both environmental impact and operational costs.

HEPA Oil Mist Collector Filters

HEPA-grade filters provide ultra-fine filtration for high-precision machining environments. They remove particles as small as 0.3 microns, ensuring that even the smallest contaminants are captured, which is essential for sensitive CNC operations and strict clean air requirements.

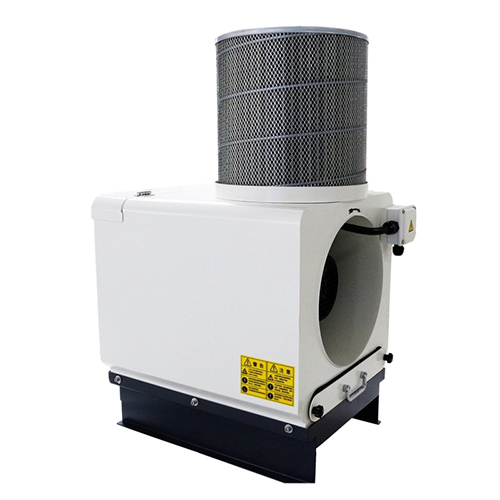

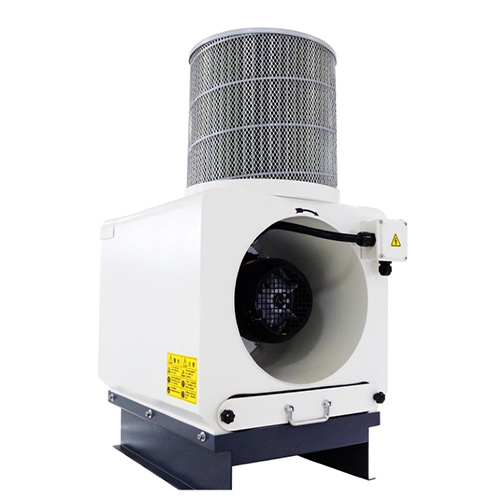

Multi-Stage Oil Mist Collector Filter Systems

For demanding industrial applications with high oil mist concentration, multi-stage systems combine mechanical, coalescing, and HEPA filtration. This approach maximizes efficiency, extends filter lifespan, and provides a cleaner working environment for both employees and machinery.

Key Factors to Consider When Choosing an Oil Mist Collector Filter

Selecting the right oil mist collector filter directly impacts performance, maintenance requirements, and overall cost-effectiveness.

Filtration Efficiency and Particle Size

High-efficiency filters capture finer particles and deliver cleaner air. Assessing filtration efficiency is critical for meeting both workplace safety standards and equipment protection needs.

Airflow Capacity and Pressure Drop

Filters must allow adequate airflow while maintaining effective mist removal. Poor airflow can reduce machine performance and increase energy costs, while improper pressure drop can damage filters or reduce filtration efficiency.

Filter Material and Durability

Industrial-grade filter materials ensure long service life, even under continuous operation. Choosing durable materials reduces replacement frequency and ensures consistent performance over time.

Maintenance and Replacement Cycle

A well-designed filter system minimizes maintenance efforts and costs. Understanding recommended replacement cycles and maintenance procedures helps avoid operational interruptions and ensures long-term reliability.

Oil Mist Collector Filter Applications Across CNC and Metalworking Industries

Our oil mist collector filters are widely used across CNC machining and metalworking sectors. They are effective for various machine types and workshop configurations, providing both health and operational benefits.

CNC Lathes and Machining Centers

Enclosed CNC machines often produce concentrated oil mist that can affect precision and surface quality. Our filters ensure consistent air cleanliness, protecting both machines and operators.

Grinding and Milling Machines

High-speed operations generate fine oil mist that can settle on machinery and finished parts. Effective filtration reduces contamination, maintains product quality, and extends machine life.

Metal Cutting and Heavy-Duty Equipment

Industrial environments with high-volume metal cutting or heavy-duty operations generate significant oil mist. Our systems are engineered to handle these challenging conditions efficiently.

Manufacturing Workshops and Factories

Installing oil mist collector filters in general manufacturing areas improves overall air quality, ensures a safer work environment, and reduces maintenance costs for all equipment operating in the facility.

Common Problems with Oil Mist Collector Filters and How to Solve Them

Even the best filtration systems can encounter issues if not properly selected or maintained. Identifying common problems helps prevent performance loss and costly downtime.

Oil Mist Collector Filter Clogging

Clogging is often caused by incorrect filter sizing, high oil mist concentration, or delayed maintenance. Regular monitoring and timely replacement are critical to avoid reduced airflow and inefficiency.

Reduced Filtration Efficiency

Filters that are saturated or installed improperly may fail to capture fine mist particles. Selecting the right filter for your specific application and following manufacturer guidelines ensures consistent performance.

Improper Installation Issues

Incorrect installation, such as wrong airflow direction or poor sealing, can lead to leakage and reduced effectiveness. Proper installation according to manufacturer instructions is essential for reliable operation.

As a manufacturer, we provide technical support and guidance to help customers avoid these issues and maintain optimal filtration performance.

Oil Mist Collector Filter Maintenance and Replacement Guide

Proper maintenance is key to ensuring that oil mist collector filters operate efficiently over time.

How Often Should an Oil Mist Collector Filter Be Replaced?

Replacement intervals vary depending on machine type, oil mist concentration, and operational hours. Regular monitoring and scheduled replacement prevent filter saturation and maintain air quality.

Cleaning vs Replacement: What’s Better?

Some pre-filters can be cleaned and reused, but high-efficiency and HEPA filters should be replaced when saturated. Cleaning may extend filter life slightly but cannot restore full filtration efficiency.

Tips to Extend Filter Lifespan

- Match filter specifications to operating conditions

- Monitor pressure drop regularly

- Conduct scheduled inspections and maintenance

Following these practices ensures the system continues to operate at peak efficiency while reducing unexpected downtime.

Customized Oil Mist Collector Filter Solutions from the Manufacturer

Standard products may not meet all industrial requirements. We provide customized oil mist collector filter solutions tailored to the specific needs of your workshop or factory.

OEM and Customized Design Options

We support OEM projects with filters designed to specific dimensions, materials, and filtration levels, enabling customers to integrate filters seamlessly into their machinery.

Matching Filters to Different CNC Machines

Filters are tailored based on machine type, airflow requirements, and oil mist concentration to ensure maximum efficiency and minimal maintenance.

Custom Airflow and Filtration Requirements

Our engineering team designs solutions for standard operations, heavy-duty environments, and high-volume oil mist scenarios. Customization ensures optimal performance in any industrial setting.

Why Choose Us as Your Oil Mist Collector Filter Manufacturer and Supplier

Selecting the right manufacturer ensures stable quality, technical support, and long-term reliability.

Direct Factory Supply and Quality Control

By controlling the entire production process, we maintain consistent performance and product quality. Our direct factory supply reduces cost and ensures timely delivery.

Global Export Experience and Certifications

Our products comply with international industrial standards and are exported worldwide. Clients benefit from proven quality and trusted technical support.

Competitive Pricing and Reliable Lead Time

Factory-direct supply reduces costs, while our manufacturing capabilities ensure prompt delivery. Reliable lead times make it easier for businesses to plan production and maintenance schedules.

How to Buy the Right Oil Mist Collector Filter for Your CNC Machines

To provide an accurate quotation, we typically need:

- CNC machine type

- Required airflow capacity

- Oil mist concentration and operating hours

We support bulk orders, OEM customization, and long-term cooperation with distributors and industrial clients, ensuring every customer receives the most suitable solution.

Conclusion

A high-performance oil mist collector filter is essential for maintaining clean air, protecting CNC equipment, and improving overall workshop efficiency. As a professional oil mist collector filter manufacturer, we provide reliable, high-efficiency, and customizable filtration solutions for CNC and metalworking industries.

FAQ

What is an oil mist collector filter?

An oil mist collector filter is a device used in CNC machines and industrial workshops to capture and remove airborne oil particles, ensuring cleaner air and protecting equipment from contamination.

How often should I replace an oil mist collector filter?

Replacement frequency depends on oil mist concentration, machine usage, and filter type. Typically, high-efficiency filters are replaced every 3–6 months, while pre-filters may last longer with proper cleaning.

Can you customize oil mist collector filters for different CNC machines?

Yes. As a manufacturer, we offer OEM and customized filter solutions to match airflow, filtration efficiency, and size requirements for various CNC and metalworking equipment.

What are the benefits of using an oil mist collector filter?

Benefits include improved air quality, reduced health risks for operators, prevention of machine contamination, longer equipment life, and compliance with industrial safety standards.

How do I choose the right oil mist collector filter for my workshop?

Consider factors such as machine type, airflow capacity, oil mist concentration, and filter efficiency. Our technical team can help you select the best solution for your specific needs.

Need Help Choosing the Right Oil Mist Collector Filter?

If you’re unsure which oil mist collector filter is best for your CNC machines or industrial workshop, our experts are here to guide you. Contact us today for a personalized consultation, and ensure your equipment stays protected while maintaining clean and safe air quality. Don’t wait until your machines or workspace are affected—get in touch now to secure the right filtration solution for your operations!