-

WhatsAPP: +86 18706448138

-

Tengzhou, Shandong, China

Oil Skimmer: A Practical Guide to Improving CNC Coolant Life and Workshop Conditions

Introduction

In CNC machining workshops, coolant performance directly affects machining quality, tool life, operating cost, and even the working environment. One common but often underestimated issue is tramp oil contamination—unwanted oils such as way oil, hydraulic oil, or lubricating oil that enter the coolant system during daily operation.

An oil skimmer is one of the simplest and most effective tools for managing this problem. Rather than replacing coolant frequently or relying solely on chemical treatments, many workshops use oil skimmers as a practical, mechanical solution to extend coolant life and stabilize machining conditions.

What Is an Oil Skimmer?

An oil skimmer is a device designed to remove floating oil from the surface of liquids—most commonly from CNC machine coolant tanks. It works by exploiting the natural affinity between oil and certain materials, allowing oil to be separated without removing large amounts of coolant.

In CNC workshops, oil skimmers are usually installed on:

- CNC lathes

- Machining centers

- Grinding machines

- Centralized coolant systems

Their primary function is to continuously remove tramp oil before it causes coolant degradation.

Why Tramp Oil Is a Serious Problem in CNC Machining

During normal machine operation, tramp oil inevitably enters the coolant system. Common sources include:

- Guideway lubrication systems

- Hydraulic components

- Spindle lubrication

- Manual oiling during maintenance

When tramp oil accumulates on the coolant surface, it can lead to several problems:

Reduced Coolant Life

Floating oil forms a barrier that limits oxygen exchange. This creates an ideal environment for anaerobic bacteria, accelerating coolant spoilage.

Unpleasant Odors and Poor Workshop Environment

Bacterial growth often causes strong odors, negatively affecting operator comfort and workplace conditions.

Unstable Machining Performance

Contaminated coolant may lose cooling and lubricating efficiency, leading to inconsistent surface finish and increased tool wear.

Increased Operating Costs

Frequent coolant replacement, tank cleaning, and disposal increase both direct costs and machine downtime.

Removing tramp oil early is one of the most effective ways to prevent these issues.

How an Oil Skimmer Works

Oil skimmers operate on a simple physical principle: oil adheres more readily than water to certain surfaces.

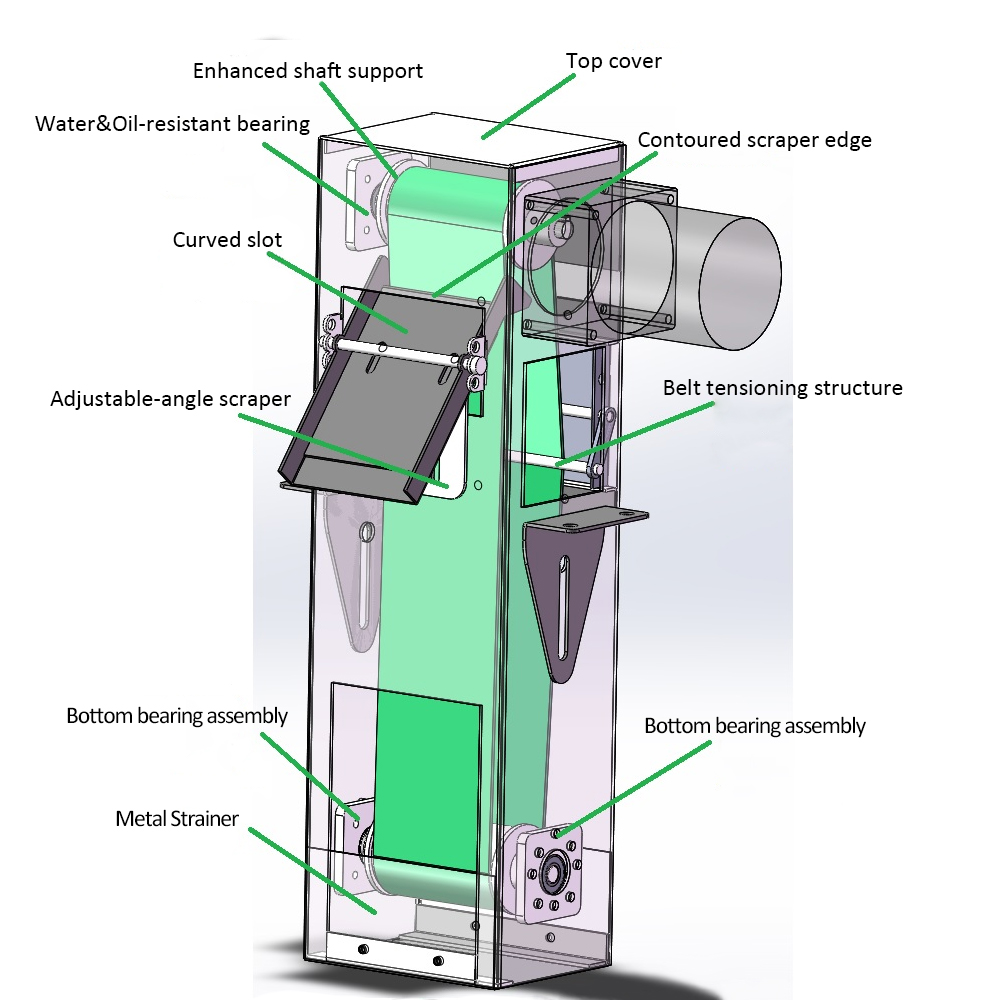

A typical oil skimmer consists of:

- A rotating medium (belt, disc, tube, or rope)

- A motorized drive system

- A scraper or wiper

- An oil collection container

As the rotating element passes through the coolant surface, it attracts floating oil. The scraper then removes the oil from the surface of the element and directs it into a collection container. Clean coolant flows back into the tank.

This process can operate continuously while the machine is running, requiring minimal operator intervention.

Common Types of Oil Skimmers Used in CNC Machines

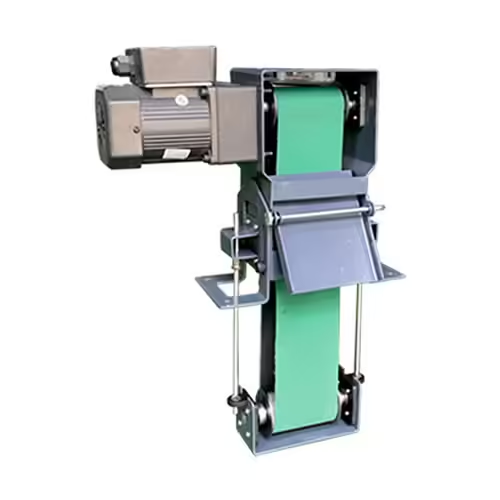

Belt Type Oil Skimmer

The belt type oil skimmer is the most widely used option in CNC workshops.

Characteristics:

Uses a continuous loop belt made of oil-attracting material

Compact structure and easy installation

Suitable for most CNC coolant tanks

Typical applications:

- CNC lathes

- Vertical and horizontal machining centers

- Small to medium coolant tanks

This type is favored for its simplicity, reliability, and cost-effectiveness.

Disc Type Oil Skimmer

Disc skimmers use a rotating disc partially immersed in the coolant.

Characteristics:

- Larger oil-contact surface

- Higher oil removal capacity

- Typically bulkier than belt skimmers

Typical applications:

- Large coolant reservoirs

- Centralized coolant systems

Tube or Rope Type Oil Skimmer

Tube or rope skimmers use a long, oil-attracting tube or rope.

Characteristics:

- Flexible installation

- Suitable for deep tanks or pits

Typical applications:

- Industrial wastewater treatment

- Large oil-water separation systems

They are less commonly used directly on individual CNC machines.

Benefits of Using an Oil Skimmer in CNC Workshops

Installing an oil skimmer provides several measurable advantages:

Extended Coolant Service Life

By continuously removing tramp oil, coolant remains chemically stable for a longer period.

Reduced Coolant Replacement Frequency

Less frequent coolant changes mean lower material costs and reduced downtime.

Improved Machining Stability

Cleaner coolant helps maintain consistent cooling and lubrication, supporting stable cutting conditions.

Better Workshop Environment

Reduced odor and cleaner coolant tanks contribute to improved operator comfort and shop cleanliness.

Lower Maintenance Workload

Less sludge buildup and fewer tank cleanings simplify routine maintenance.

Where to Install an Oil Skimmer on a CNC Machine

Proper installation is essential for effective oil removal. Common installation locations include:

- Coolant tank surface: Direct access to floating oil

- Return channel: Where coolant flows back into the tank

- Central coolant system reservoir: For workshops using multiple machines

The skimmer should be positioned where tramp oil naturally accumulates and where coolant turbulence is minimal.

Oil Skimmer vs. Frequent Coolant Replacement

Some workshops address coolant contamination by replacing coolant frequently. While this may solve short-term issues, it is not always cost-effective.

A typical comparison:

- Coolant replacement involves material cost, labor, machine downtime, and disposal

- Oil skimmers operate continuously with low energy consumption and minimal maintenance

In many cases, oil skimmers significantly reduce the overall cost of coolant management over time.

How to Choose the Right Oil Skimmer for CNC Applications

When selecting an oil skimmer, consider the following factors:

- Coolant tank size and depth

- Level of oil contamination

- Machine type and layout

- Available installation space

- Continuous or intermittent operation requirements

For most CNC lathes and machining centers, compact belt type oil skimmers provide a good balance between performance and simplicity.

Conclusion

Tramp oil contamination is an unavoidable part of CNC machining, but its impact can be effectively controlled. Oil skimmers offer a simple, mechanical, and reliable method to improve coolant condition, extend service life, and maintain a cleaner workshop environment.

As part of a broader coolant management strategy, oil skimmers are widely adopted in CNC workshops seeking stable machining performance and lower operating costs.

To stay updated with our latest news, products, and technical insights, you are welcome to follow us through the channels below:

- 🌐 Official Website

- ▶ YouTube