-

WhatsAPP: +86 18706448138

-

Tengzhou, Shandong, China

Why Your Shop Needs an Advanced Oil Mist Collector Filter

This blog explores why an oil mist collector filter is indispensable for your shop, diving into its benefits, features, and long-term value.

Table of Contents

Introduction

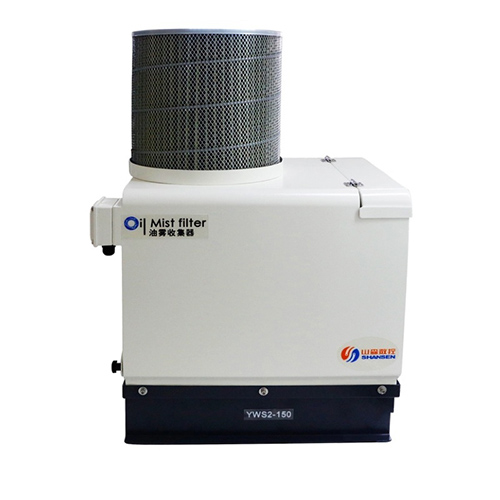

In modern manufacturing, maintaining a clean and safe workshop environment is critical. An oil mist collector filter is an essential tool for shops utilizing CNC machines, as it captures and removes oil mist, aerosols, and fine particles generated during machining processes. At Shansen, a leading developer and manufacturer of CNC machine electrical components, we understand the importance of integrating advanced filtration systems to enhance workplace safety and efficiency. This blog explores why an oil mist collector filter is indispensable for your shop, diving into its benefits, features, and long-term value.

The Role of Oil Mist Collector Filters in CNC Machining

CNC machining produces oil mist as a byproduct of cutting, grinding, and turning operations. Without proper filtration, this mist can settle on equipment, floors, and even workers, creating hazardous conditions. An oil mist collector efficiently captures these particles, ensuring cleaner air and a safer workspace. Shansen’s expertise in CNC machine components underscores the need for high-quality filtration systems to complement precision machining, protecting both machinery and personnel.

How Oil Mist Collectors Work

An oil mist collector operates by drawing contaminated air through a series of filtration stages, typically including pre-filters, main filters, and sometimes HEPA filters for ultra-fine particles. The system traps oil mist and aerosols, returning clean air to the shop. Advanced models, like those compatible with Shansen’s CNC systems, use multi-stage filtration to maximize efficiency, ensuring even microscopic particles are captured.

Health Benefits of Using an Oil Mist Collector Filter

Exposure to oil mist can lead to respiratory issues, skin irritation, and long-term health risks for workers. An oil mist collector mitigates these dangers by removing harmful particles from the air. By investing in a high-quality oil mist collector, shop owners demonstrate a commitment to employee well-being, reducing absenteeism and improving productivity. Shansen prioritizes workplace safety, and our solutions are designed to integrate seamlessly with advanced filtration systems.

Compliance with Workplace Safety Regulations

Many regions enforce strict regulations on air quality in industrial settings. An oil mist collector helps shops comply with standards set by organizations like OSHA or local environmental agencies. By maintaining clean air, shops avoid costly fines and enhance their reputation as responsible employers. Shansen’s CNC components are engineered to support compliance, ensuring your shop meets industry standards.

Enhancing Equipment Longevity with Oil Mist Collector Filters

Oil mist can accumulate on CNC machines, leading to corrosion, reduced precision, and costly repairs. An oil mist collector filter prevents this buildup, extending the lifespan of your equipment. For shops using Shansen’s high-performance CNC electrical components, integrating an oil mist collector ensures optimal machine performance and reduces maintenance costs over time.

Key Features to Look for in an Oil Mist Collector Filter

When selecting an oil mist collector filter, consider the following features to ensure maximum effectiveness:

| Feature | Description | Benefit |

|---|---|---|

| Multi-Stage Filtration | Includes pre-filters, main filters, and optional HEPA filters | Captures particles of varying sizes for cleaner air |

| High Capture Efficiency | Removes up to 99% of oil mist and aerosols | Ensures a healthier and safer workspace |

| Compact Design | Fits easily in small or crowded shops | Saves valuable floor space |

| Low Maintenance | Easy-to-replace filters and self-draining systems | Reduces downtime and maintenance costs |

| Energy Efficiency | Low-power consumption motors | Lowers operational costs |

| Durable Construction | Made from corrosion-resistant materials | Ensures long-term reliability |

This table highlights essential features that make an oil mist collector a valuable addition to any shop, particularly those using Shansen’s precision CNC systems.

Environmental Impact of Oil Mist Collector Filters

Beyond health and equipment benefits, an oil mist collector contributes to environmental sustainability. By capturing oil mist before it escapes into the atmosphere, these systems reduce air pollution and minimize the shop’s environmental footprint. Shansen’s commitment to innovation extends to supporting eco-friendly practices, making our CNC solutions compatible with advanced filtration technologies.

Reducing Waste with Reusable Filters

Some oil mist collector filters feature reusable or washable components, reducing waste and operational costs. These systems align with sustainable manufacturing practices, allowing shops to balance profitability with environmental responsibility. Shansen encourages the adoption of such technologies to create greener workshops.

Cost Savings from Implementing Oil Mist Collectors

While the initial investment in an oil mist collector may seem significant, the long-term savings are substantial. Reduced equipment maintenance, lower healthcare costs, and improved energy efficiency all contribute to a strong return on investment. For shops using Shansen’s CNC components, integrating a high-quality oil mist collector maximizes operational efficiency and minimizes unexpected expenses.

Energy Efficiency and Operational Savings

Modern oil mist collector are designed with energy-efficient motors and low-maintenance components, reducing electricity and upkeep costs. By pairing these systems with Shansen’s advanced CNC technology, shops can achieve significant savings while maintaining high productivity levels.

Why Shansen Recommends Advanced Oil Mist Collector Filters

As a leader in CNC machine electrical components, Shansen recognizes the synergy between precision machining and clean air systems. An advanced oil mist collector filter not only protects your equipment but also enhances the performance of our cutting-edge CNC solutions. Our expertise in manufacturing high-quality components ensures that your shop can integrate filtration systems seamlessly, boosting overall efficiency.

Conclusion

An oil mist collector filter is more than just a piece of equipment—it’s a critical investment in your shop’s safety, efficiency, and sustainability. From protecting worker health to extending equipment lifespan and ensuring regulatory compliance, the benefits are undeniable. Shansen’s commitment to excellence in CNC technology makes us a trusted partner in building cleaner, more efficient workshops. Contact us today to explore how an oil mist collector filter can transform your operations and elevate your shop’s performance.

FAQ

What is an oil mist collector filter?

An oil mist collector filter is a device that captures oil mist, aerosols, and fine particles generated during CNC machining, ensuring cleaner air in the workshop.

How often should oil mist collector filters be replaced?

Replacement frequency depends on usage and filter type, but most systems require filter changes every 6-12 months. Regular maintenance ensures optimal performance.

Can an oil mist collector filter be used with any CNC machine?

Yes, most oil mist collector filters are compatible with a wide range of CNC machines, including those using Shansen’s electrical components. Always check specifications for compatibility.