-

WhatsAPP: +86 18706448138

-

Tengzhou, Shandong, China

Why an Automatic Lathe Machine is Essential for Modern Manufacturing

Manufacturer of high-precision automatic lathe machines. Ideal for bulk orders, industrial production, and commercial projects.

Welcome to My Blog!

Before we dive into the content, if you’re interested in our products or have any questions, please feel free to visit our Contact Us page on the website. Our team is ready to assist you with inquiries, orders, or any support you may need.

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Automatic lathe machines are revolutionizing modern manufacturing by combining precision, speed, and automation. Designed for manufacturers, fabricators, and engineering companies, these machines streamline production, reduce labor costs, and ensure consistent product quality. By integrating advanced technology, businesses can maintain competitive advantages while meeting high-volume production demands.

Overview of Automatic Lathe Machines

Automatic lathe machines are specialized equipment designed to perform precise turning operations with minimal human intervention. They are widely used in industries that require high-speed, high-accuracy machining for components of various sizes and materials.

What is an Automatic Lathe Machine?

An automatic lathe machine is a machine tool that rotates a workpiece while tools perform cutting, drilling, or shaping operations automatically. Unlike manual lathes, these machines can handle complex designs with consistent precision, making them ideal for mass production.

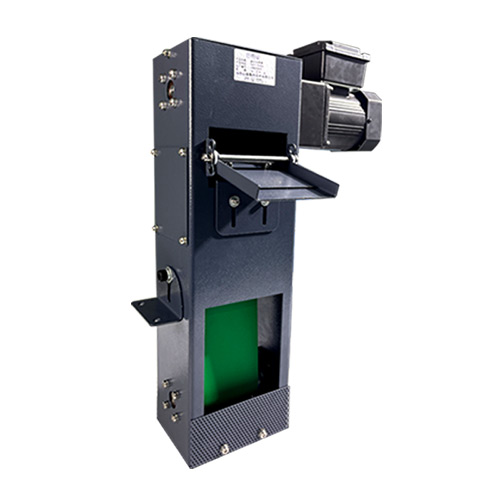

Key Components and Features

Automatic lathes typically include a spindle, tool turret, control panel, and feeder mechanism. Modern models feature CNC controls, programmable cycles, and high-speed operations that significantly enhance productivity. These features allow manufacturers to achieve complex shapes efficiently while maintaining uniform quality.

Types of Automatic Lathe Machines

There are several types of automatic lathe machines, including cam-operated, CNC-controlled, and multi-spindle models. Each type caters to different production requirements, from small precision parts to large-scale industrial components. Understanding the differences helps businesses select the right machine for their needs.

Advantages of Using Automatic Lathe Machines

Automatic lathe machines offer significant benefits that can transform manufacturing processes. They increase production efficiency, reduce errors, and ensure consistent output, making them essential for modern industrial operations.

- Increased Production Efficiency and Precision: Machines operate continuously at high speeds, reducing cycle times and delivering precise dimensions for each component.

- Reduced Labor Costs and Human Error: Automation reduces dependency on manual labor and minimizes mistakes that can occur with manual machining.

- Consistent Quality for Large-Scale Manufacturing: With programmable operations, every part produced meets exact specifications, maintaining high-quality standards.

Applications Across Industries

Automatic lathe machines are versatile tools used in a wide range of industries. Their precision and efficiency make them suitable for both small and large-scale manufacturing projects.

- Automotive and Aerospace Components: High-speed lathes produce shafts, gears, and other precision parts crucial for vehicles and aircraft.

- Electronics and Precision Parts: Small, intricate components like connectors and pins can be manufactured accurately and efficiently.

- Custom Metal and Plastic Manufacturing: Automated lathes allow fabrication of bespoke parts with complex geometries, enhancing manufacturing flexibility.

Choosing the Right Automatic Lathe Machine

Selecting the right automatic lathe machine is crucial to optimizing production efficiency and cost-effectiveness. Businesses should consider factors such as production volume, material compatibility, and automation level when making their choice.

Considering Production Volume

High-volume production requires machines capable of continuous operation without frequent maintenance. Choosing a model with sufficient spindle capacity and speed ensures that your factory meets demand consistently.

Material Compatibility

Different lathes are optimized for specific materials such as metals, plastics, or composites. Ensuring the machine can handle the required material types will prevent wear and improve overall efficiency.

Machine Size and Automation Level

The physical size of the lathe and the level of automation are important for workflow integration. Fully automated CNC lathes may offer higher precision and flexibility but require more initial investment than semi-automatic models.

Maintenance and Longevity Tips

Regular maintenance is essential to maximize the lifespan and performance of automatic lathe machines. Proper care minimizes downtime and ensures long-term reliability.

- Regular Cleaning and Lubrication: Removing debris and applying lubricant prevents wear and tear on moving parts.

- Replacing Worn Parts on Schedule: Timely replacement of spindles, tool holders, and belts reduces the risk of breakdowns.

- Importance of Professional Servicing: Engaging certified technicians for maintenance guarantees that machines operate safely and efficiently.

Cost Considerations and ROI

Investing in an automatic lathe machine can offer significant long-term returns, even if the initial cost is substantial. Businesses should evaluate both the upfront investment and ongoing operational savings.

- Initial Investment vs Long-Term Savings: High-efficiency machines reduce labor costs and production errors, offsetting the initial expense over time.

- Energy Efficiency and Maintenance Costs: Modern automatic lathes consume less power and require minimal maintenance, improving overall profitability.

- Case Studies of ROI for Manufacturers: Companies adopting automated lathes have reported faster production cycles, lower defect rates, and improved client satisfaction.

Why Partner with a Manufacturer Directly

Working directly with a manufacturer provides numerous advantages for businesses looking to acquire automatic lathe machines. Direct partnerships ensure customization, support, and reliable supply.

- Customization Options for Specific Production Needs: Manufacturers can tailor machine configurations, tool options, and automation levels to suit your project.

- Bulk Orders and Reliable Supply: Direct ordering ensures availability for large-scale projects and minimizes delays.

- Technical Support and Training: Manufacturers provide training and ongoing support to help teams operate machines efficiently and safely.

Client Testimonials and Success Stories

Many businesses have improved efficiency and reduced costs by integrating automatic lathe machines into their production lines. Retailers, component manufacturers, and engineering firms consistently highlight the precision, reliability, and scalability of our machines.

Success Stories:

- Automotive parts manufacturers reduced production cycle times by 30% with CNC automatic lathes.

- Electronics component suppliers improved accuracy and reduced defect rates, increasing client satisfaction.

- Fabrication shops expanded capabilities by using multi-spindle lathes for high-volume, complex parts.

Conclusion

Automatic lathe machines are indispensable for manufacturers seeking precision, efficiency, and consistency. By investing in high-quality machines directly from a reliable manufacturer, businesses can optimize production, reduce costs, and meet market demands effectively.

FAQ

What is an automatic lathe machine?

An automatic lathe machine is a tool that performs turning, cutting, and shaping operations automatically. It provides high precision and efficiency for large-scale manufacturing.

What are the main benefits of using an automatic lathe machine?

Automatic lathe machines improve production speed, reduce labor costs, and ensure consistent quality for components, making them ideal for commercial and industrial projects.

Which industries use automatic lathe machines?

They are widely used in automotive, aerospace, electronics, and custom metal or plastic manufacturing for producing precision parts efficiently.

Can I customize an automatic lathe machine for my production needs?

Yes, manufacturers offer options for material compatibility, automation level, and modular configurations to match specific production requirements.

How do I maintain an automatic lathe machine for long-term performance?

Regular cleaning, lubrication, timely replacement of worn parts, and professional servicing ensure reliable operation and extend the machine’s lifespan.

Need Help Choosing the Right Automatic Lathe Machine?

If you’re unsure which automatic lathe machine is best for your production line or commercial project, our experts are here to help. Contact us today for a personalized consultation, and ensure your manufacturing process is efficient, precise, and cost-effective. Don’t wait—get in touch now to elevate your production capabilities!